Anti_Climax

Well-known member

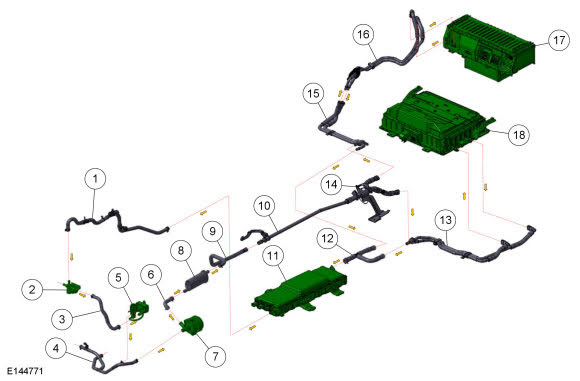

So, at this point we've replaced:

When I last picked it up the tech had been unable to get the battery to go above 86F. That's while it's in the 60's outside. They put it on their L2 charger and called me to come get it. They felt confident it was solved after the chiller block replacement.

By the time I got there it had finished charging and was at 100F - it would have kicked on the chiller at 97F. I took the freeway route home, putting about 25 miles on it and had it at 108F when it was plugged into my L2. Again, while it's in the 60s for ambient temp.

A half hour later, it had climbed to 113F and stayed there while charging for about 2 hours. After that 2 hours it ran the chiller alone for another hour, during which the temp dropped to 111F and I unplugged it so it could ACTUALLY cool off and stop wasting electricity.

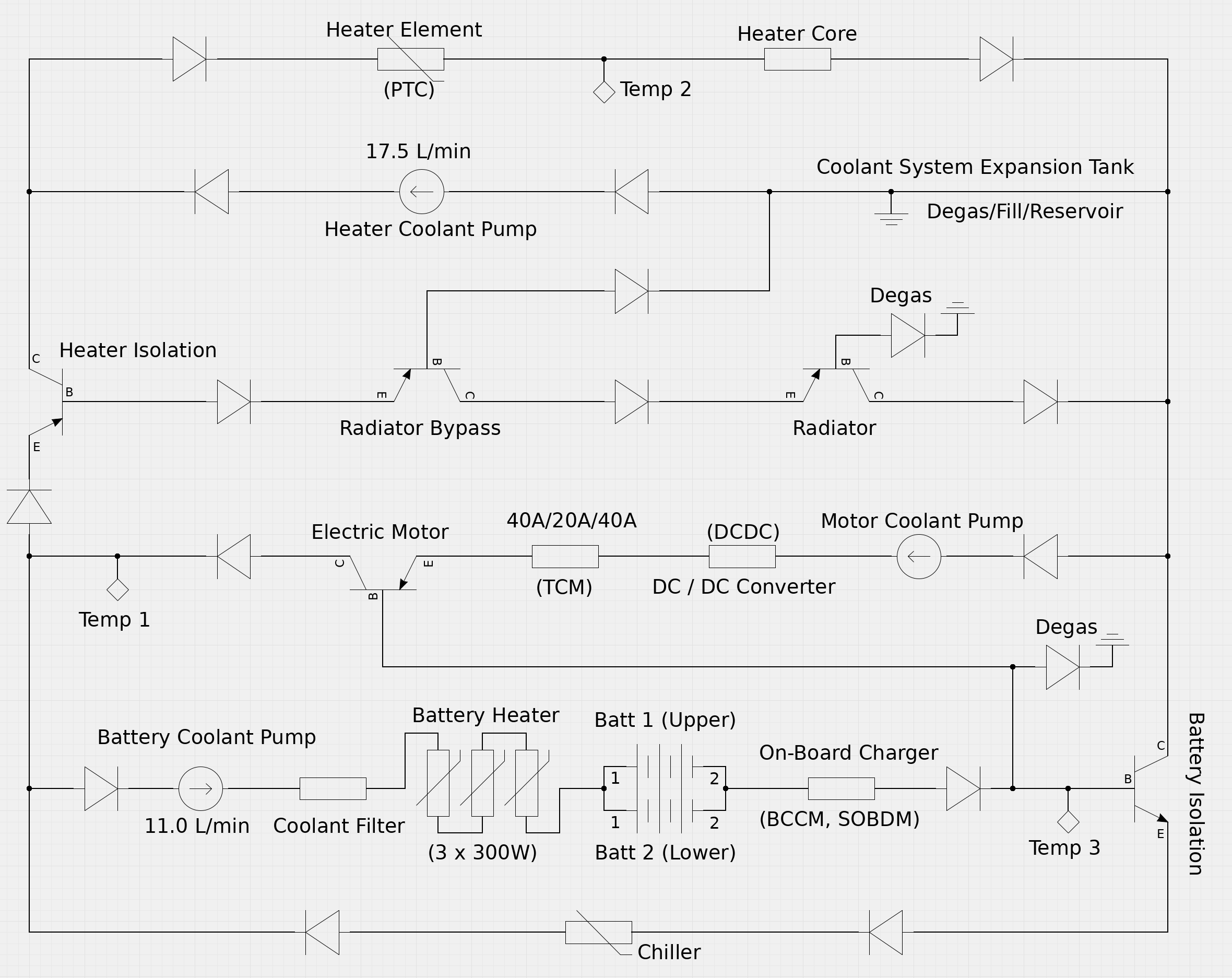

So, at this point I need to charge on L1 anytime my battery is anywhere near the chiller trigger temp, or it will start running the chiller and somehow adding thermal energy instead of taking it away.

I have a feeling I'm going to need to pull the battery or otherwise test the coolant flow through different parts of the system to see if something has gummed up.

Anyone have recommendations for in-line flow meters? Is it possible to even "get to" the coolant channels on the pack if I go through the effort of pulling it out?

- The AC compressor

- The AC compressor harness/pigtail

- Battery loop pump

- Coolant Filter X2

- Replace Chiller line X2

- Replace Chiller block

When I last picked it up the tech had been unable to get the battery to go above 86F. That's while it's in the 60's outside. They put it on their L2 charger and called me to come get it. They felt confident it was solved after the chiller block replacement.

By the time I got there it had finished charging and was at 100F - it would have kicked on the chiller at 97F. I took the freeway route home, putting about 25 miles on it and had it at 108F when it was plugged into my L2. Again, while it's in the 60s for ambient temp.

A half hour later, it had climbed to 113F and stayed there while charging for about 2 hours. After that 2 hours it ran the chiller alone for another hour, during which the temp dropped to 111F and I unplugged it so it could ACTUALLY cool off and stop wasting electricity.

So, at this point I need to charge on L1 anytime my battery is anywhere near the chiller trigger temp, or it will start running the chiller and somehow adding thermal energy instead of taking it away.

I have a feeling I'm going to need to pull the battery or otherwise test the coolant flow through different parts of the system to see if something has gummed up.

Anyone have recommendations for in-line flow meters? Is it possible to even "get to" the coolant channels on the pack if I go through the effort of pulling it out?